Here at Because We Can, we work with a variety of robots and robotic tools. We've almost a decade of experience with it, and we've learned a great deal along the way. And we love to share what we've learned with you.

We interchangeably use the terms 'robot', 'robotic tools', and 'automation' to all mean the same thing: whether by a physical robot, custom computer code, CNC tool, or some combination therein, you're automating some task such that it's not being done by the labor of a person.

When thinking about having a robot do a job, it's important to know why you're going to have the robot do something rather than a person. Robots aren't always better than people, and can be expensive to set up, so you run the risk of spending a lot of time and money with not enough return. Or actually making the end result worse by trying to automate it. Automating something doesn't automatically make it better, and robots aren't great at everything.

We've found that there are four levels of tasks one can give a robot, each increasing in complexity of what the robot can do versis a person. Each one has it's own challenges and risks, so it's important to know where the task you're looking to automate falls. Critically thinking of it in this way will help you from making a costly mistake, and make the best use of automation for your company.

Level One: Same Job, Only Cheaper.

This is a task where it doesn't really matter if the task is being done by a person or a robot. Packing boxes, sorting/loading parts, moving pallets around a warehouse, and other rather basic tasks are good examples what we call Same Job, Only Cheaper. It's where the only value added by doing the task with a robot is that, once the robot is setup, it can do the job cheaper than a person can. Maybe that's because the robot is able to work 24/7, maybe it's because automating the task frees up someone to do higher-value work, maybe it's because the robot replaces several workers and thus is just plain cheaper over time. But what's key here is that whatever the task is, it's not that the robot is that much better at it, it's really just a matter of economics. So when automating this sort of task, the setup and ongoing maintenance costs of the automation are really important to keep under control. Also it's important to remember that robots tend to be very non-adaptable, and can be expensive to re-tool when the task changes. So the economics of it might not work out if retooling costs keep eating up any savings from having a robot do the job instead of a person. People are smart, flexible, and adaptable. Robots aren't.

Level Two: Robot Does It Better.

This is a task where a robot can do the task better than a person. Repetitive production welding, assembly line painting/assembly, basic CNC milling, and other tasks that depend upon accuracy and repeatability are good examples of tasks we call the Robot Does It Better. The value add is obvious, for here the robot is obviously better at the task than a person. But it's important to really understand the task, and if it's really true that the robot is better in this specific instance. While a robot can make a great production welder, being more consistent than a person, if the welding requires great finesse, lots of one-off situations (like repairing elements), or hard-to-reach locations, a person could still be better in the bigger picture. Because setting up the robots takes a non-trivial amount of time and money, it may be better for some tasks to be handled by a skilled person rather than a robot, even if theoretically the robot could do a more accurate and consistent job once set up. Skilled people can make amazing things, robots can only do exactly what you set them up to do.

Level Three: Robot Makes It Easy.

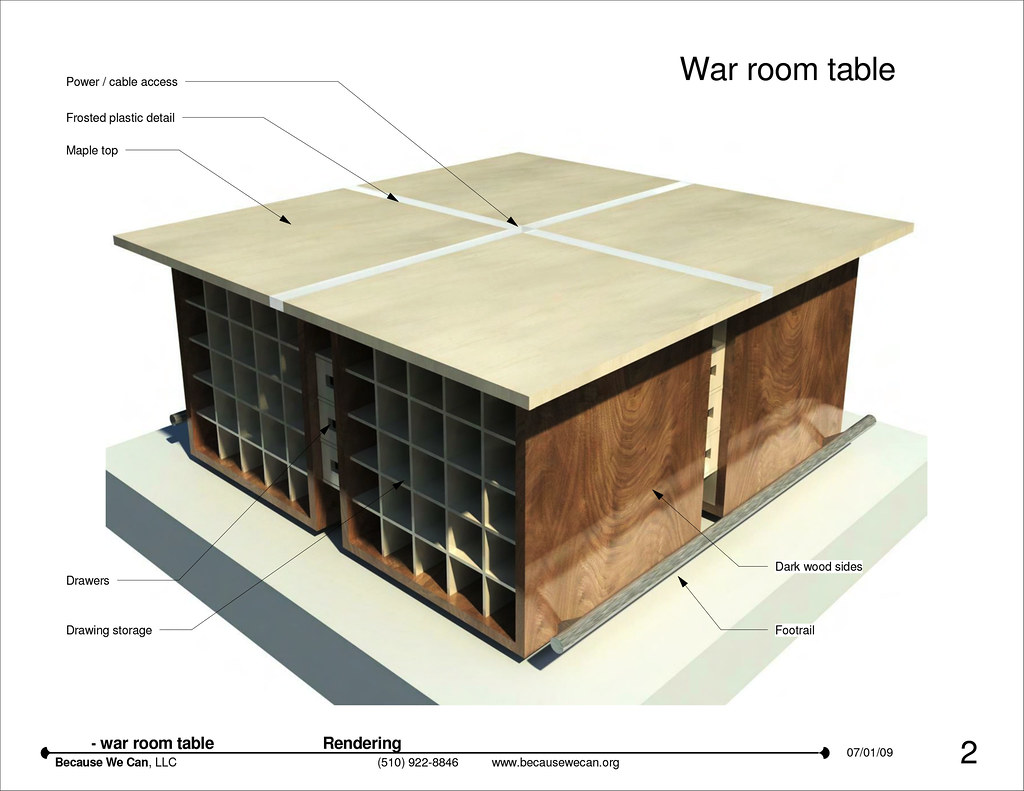

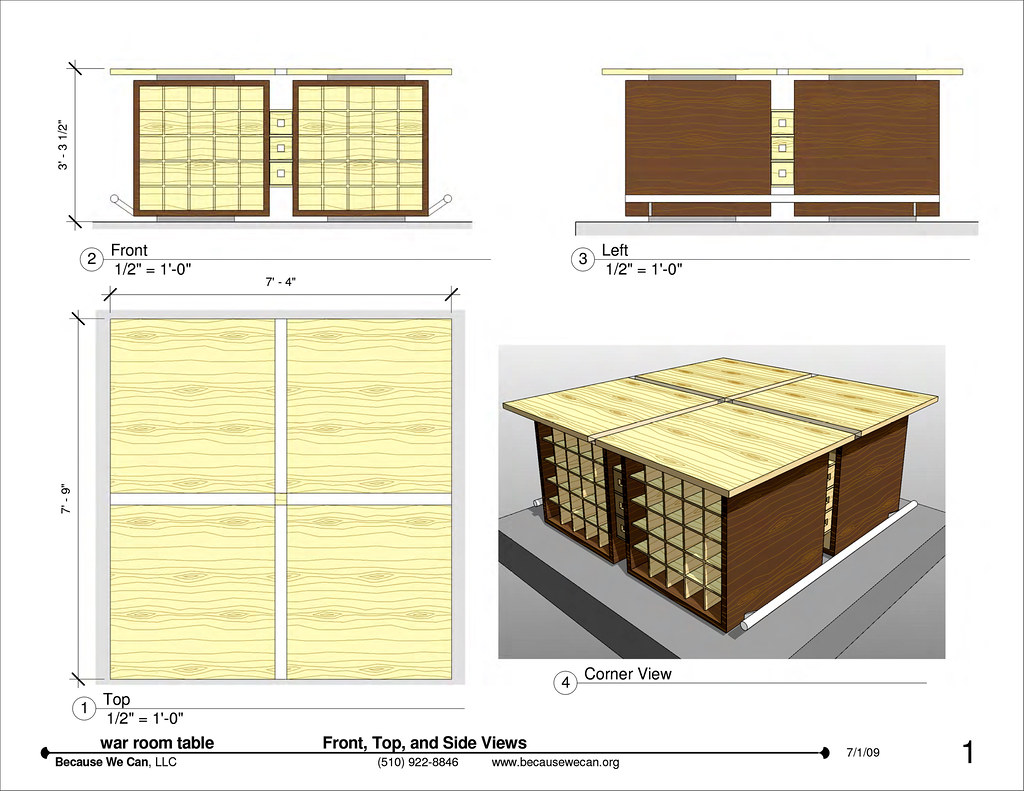

This is a task where not only does a robot do it better, but it makes something that would normally be unbearably complex simple. Complex CNC milling, complex sheet metal folding / punching, complex assembly, and other tasks where every part is unique and there are many parts are good examples of what we call the Robot Makes It Easy. While it would be time-consuming and difficult for a person to cut out hundreds of different unique parts, it's trivial for a robot to do so. This is an area we here at Because We Can are very familiar with, as many of our designs would be far too complex to produce economically by hand. It's an exciting area where working with a robot can add a lot of value. However, while we cut out almost all our parts using robotic tools, we still hand-assemble everything. The key with tasks like this is to use the robot for what it's great for, and use the people for what they are great for. Because we're very rarely making the same thing twice, and we pride ourselves on our high level of craftsmanship of what we make, we've found that the combination of robot-cut parts and skilled assembly and finishing is a winning combination for the kind of work we do.

Level Four: Robot Makes It Possible.

This is a task that can only be done by a robot, and simply can't be done by a person. Working in extremely hazardous locations, trochoidal milling processes, additive/subtractive combined manufacturing, and other tasks that are only possible by using a robot are good examples of tasks we call the Robot Makes It Possible. A great example here is the aforementioned trochoidal milling, A.K.A. 'high speed toolpaths', where a CNC machine moves in an incredibly complex and fast series of arc motions no person would be able to do, no matter how talented a machinist, to cut out complex parts significantly faster. It's not just that the robot is better at this task, it's that there is no way a person could even do the same task in the same way. This is an area where robots can add a significant amount of value, and in some instances can even be the basis for an entire company, invention, or industry. However these are also some of the most complex tasks to use a robot for, requiring either expensive software, talented engineers, or in many cases both. These tasks also require a great deal of vision, for much of the time it's something that's never really been done that way before. So these tasks can also require a great deal of creativity. However, thankfully, due to modern software, sometimes these sorts of tasks can be made accessible. For example, Fusion 360's CAM module does HSM toolpathing, and even makes the process very easy and accessible to even beginning machinists. So the real risk of these tasks is either trying to do them in a way that's too complex, or re-inventing a solution someone else already has that's better than what you came up with. If you think it's only possible with a robot, then you want to do your research and legwork, and find the very best way to only do it with a robot.

While automation is a powerful force, robots are totally awesome, and we dearly love our CNC tools, just like with any technology knowing when and how to apply it is the key to great success. We think that the real money is in empowering people, not replacing them, and that trying to fully automate everything quickly has diminishing returns. People working together with robots can make better, more amazing things more efficiently than robots alone ever could.

We hope our four levels are useful to your thinking, and we'd love to hear what you may have discovered working with these tools too.